Our expanded machining capabilities complement our existing injection molding and extrusion expertise, allowing us to offer you even more versatile solutions for your polymer products, all under one roof.

Let's get your project started today! Complete the form to contact us.

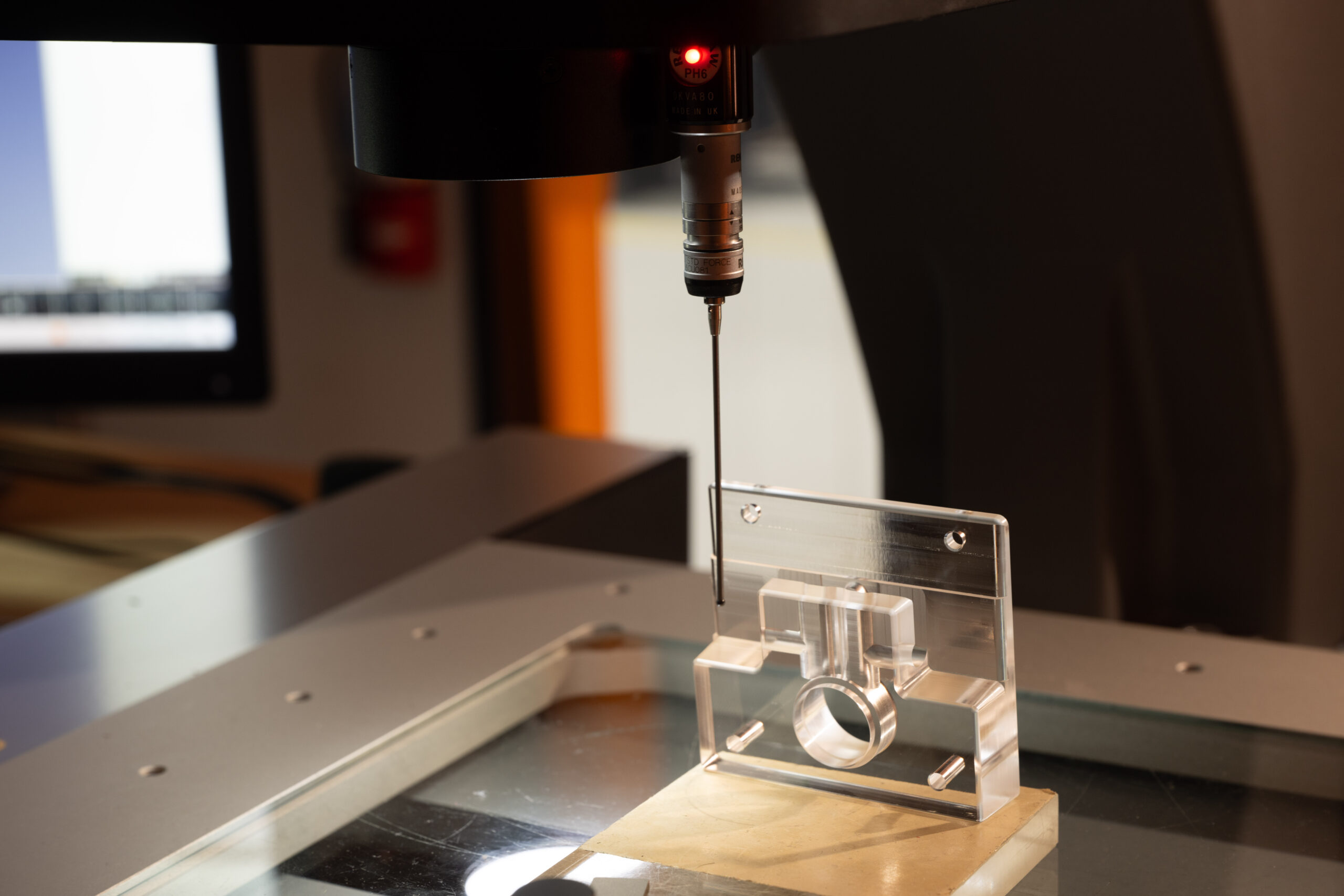

Our state-of-the-art facilities and 50+ years of experience in plastic fabrication position us as a leader in delivering tight-tolerance components with extraordinary precision to meet even the toughest product demands.

Our CNC machining operations are designed to deliver exceptional results:

Our machining capabilities allow injection molding customers to rapidly prototype parts before committing to full-scale production. This approach enables cost-effective small to medium production runs, helping make it easier to test and refine designs. Additionally, secondary machining operations provide enhanced precision or the ability to incorporate additional features into molded parts.

Extrusion customers benefit from our ability to custom machine extruded profiles to meet specific design requirements. We can transform standard extrusions into fully functional end-use parts, eliminating the need for additional processing. Our machining capabilities also support the creation of complex prototypes before investing in dedicated extrusion tooling.

At Pexco, our machining services offer a comprehensive, one-stop solution for all polymer manufacturing needs. Customers have the flexibility to enhance or customize existing Pexco products to better suit their applications. By combining multiple manufacturing processes, we empower our customers to develop innovative solutions that push the boundaries of what’s possible.

With multiple locations across North America, a skilled team of over 850 employees, and advanced technology, Pexco is uniquely equipped to meet your custom manufacturing needs, wherever you are.

Our extensive footprint includes multiple locations, over 850 employees, and advanced machinery across North America.

800K+ Sq. Ft. of Manufacturing Space

150+ Extrusion Lines

25+ Co-Extrusion Lines

800K+ Sq. Ft. of Manufacturing Space

150+ Extrusion Lines

25+ Co-Extrusion Lines

By choosing Pexco for your machining projects, you’re not just getting a service provider; you’re gaining a partner committed to your success. Our team of experts is ready to work closely with you to optimize your designs, select the best materials, and deliver high-quality parts that meet your exact specifications.

Learn more about our machining capabilities by reading our blog.